Imagine a late September day. Texas is trying to slip into Fall but Summer just isn’t letting go. It’s still hot and dry. I walked out to let the dogs out in the morning and I hear someone’s irrigation pump just screaming for help. In my mind I’m thinking, poor guy’s pump is about to fail, glad I’m not that guy. It sounded deep in the cove. I thought it was my next door neighbor’s neighbor. Boy was I wrong. It took a couple of days to figure out my lawn wasn’t getting the water it needed. I have a BeeHive setup so I can access my irrigation system using an app on my phone. I quickly checked the statistics and the app said it watered my lawn. Clearly it did not as the sidewalks were bone dry. It was easy to test, I just manually triggered a watering test and the system switched on but no water was flowing. I new right then that I was that guy. Time to shift gears and troubleshoot the problem.

Troubleshooting

You see my back ground is technical. And my analytical brain is wired for this kind of stuff. Not to mention that 5 years ago I completely replaced my irrigation pump, which is another story. I assumed this would be an easy fix. I already had an idea of what happened. However, since retiring I’ve been working with AI quite a bit. I thought this is great time to use AI and test how good it has become at troubleshooting. If you’ve read some of my other projects you’ll see how I engaged AI to help me better understand the problem space. In my opinion it’s real helpful, but you have to be sharp because it doesn’t necessarily do all the work.

To get things started, I assumed the problem had to do with the motor shaft seizing up. The reason I started with this assumption is because I could hear the 24volt DC switch engaging when I started up the system. The is the command signal from my BeeHive system. Following the switch engagement I could hear the motor attempting to start. It was a familiar humming sound meaning the motor was trying to engage but something was stopping it from kicking on. Eventually the fail safe circuit clicked on and the motor shut down. Armed with that knowledge I engaged AI and after the initial conversation we began to dig in.

AI: Want to do a quick autopsy before replacing it?

Me: What do you suggest? Remove the pump and take it apart?

AI: Let’s do a clean, methodical autopsy—nothing hasty or destructive. You’ll want to validate whether the failure was electrical, mechanical, or environmental before you commit to a replacement. Here’s a step-by-step teardown plan tailored to the WAYNE WLS200:

The recommended troubleshooting points were:

- Check power and breaker status – Having already done this step it wasn’t necessary

- Test motor windings – This required the use of a multimeter but I didn’t do this first

- Inspect for leaks or corrosion – Having visually inspected my pump proved this wasn’t the issue

- Try a manual spin – This was my first choice given the steps listed

Anytime you’re dealing with an electrical device, make sure the power is disconnected before starting. This is a 220 volt system and an electrical accident will be serious. I take safety very seriously and you should too. After turning off the breaker box to the pump I removed the back plate. What you might not know is the motor shaft sticks out through the back of the motor. It is designed with a slot so that during service a screw driver can manually manipulate the motor movement. You should be able to move it with your fingers too. This would turn out to be a critical piece of information. In my case, I was unable to turn the shaft, even with a screw driver. The conclusion at this point was the motor has seized. A new pump is about $500 for reference and this pump was only about 4 1/2 years old. According to AI a pump should last between 5 and 10 years depending on the quality of the material being pumped. In my case, I pump silty water from the lake to irrigate my lawn. But still 4 1/2 years feels too young. After another 20 to 30 minutes of conversation with AI, I decided the next step was to remove the pump and bring it up to my workshop.

Tear Down

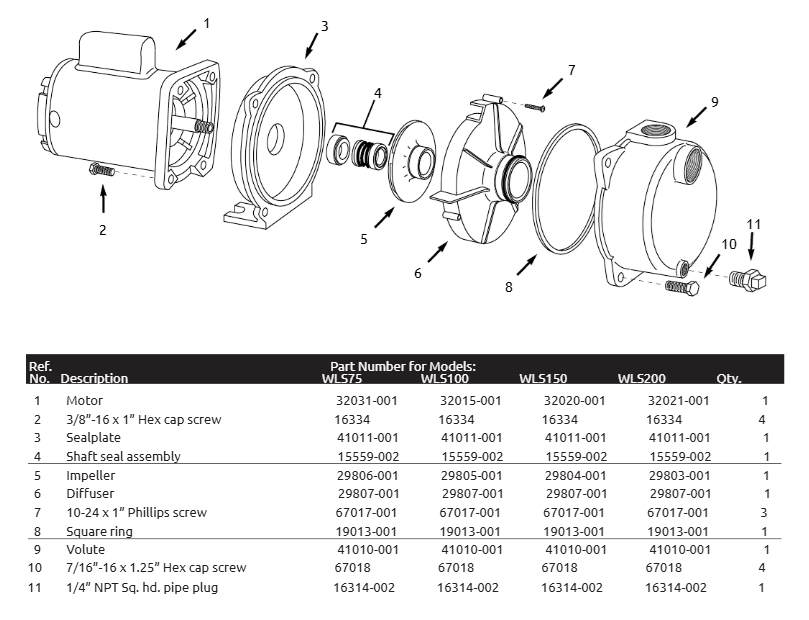

Now that the pump was in my workshop I began taking it apart. This really isn’t hard, just requires removing some bolts holding everything together. It’s worth showing the actual pump diagram at this point. I didn’t realize it at the time but knowing the parts involved with the pump is also critical information. Below shows the actual diagram of the pump along with the view of the pump with the Volute removed. At this point it looks normal and you can see the sedimentation from the silty water and it’s effect on the cast iron pump.

After removing the Volute, I still could not spin the motor shaft so I decided to go ahead and remove the Diffuser. Behind the Diffuser sits the Impeller. That is what the motor shaft spins and that is the work horse to create the vacuum to draw in the water and push it up the hill. I uploaded that same picture to AI to see what it would say.

Me: Here is the image of the pump after opening it up

AI: 🧠 Initial observations from the impeller-side image

White residue and corrosion around the central cavity suggest water intrusion past the seal—likely a failed shaft seal or gasket.

Rust and grime buildup on the housing and bolt area point to prolonged exposure to moisture, possibly from rain or lake mist.

Greasy, dark deposits could be from burnt oil or motor winding failure—especially if the motor overheated while trying to start.

🔍 What this tells us

The pump likely ran dry or under strain for a while, causing seal failure and possibly motor burnout.

The impeller cavity looks like it may have had sediment or biofilm buildup, which could’ve jammed the impeller or stressed the motor bearings.

If the motor shaft still won’t turn after impeller removal, the motor is seized internally—likely beyond repair.

Funny thing is that none of those problems listed was my problem. AI is a fantastic troubleshooting tool but it requires a human brain to still sift through the knowledge stack and pick out what is truly important. Already I’m thinking AI is off it’s rails but I still didn’t have a smoking gun. Time to remove the Diffuser. Only 3 screws hold the Diffuser to the pump. Be careful removing those screws, corrosion might make it difficult and you don’t want to strip the heads. Sitting behind the Diffuser is the Impeller and as soon as I removed the Diffuser, I found my smoking gun. Here are the photos.

That wasn’t supposed to happen. When the Diffuser is removed, the Impeller should have stayed attached to the motor shaft and should sit immediately in front of the seal plate. What you see in the first image is the Impeller stuck inside the Diffuser and the second image shows the motor shaft sticking out of the Sealpate but the Shaft Seal Assembly is still attached to the motor shaft. That means the Impeller broke off of its mount that that is why my pump wasn’t working. Indeed the motor shaft now spins freely. My smoking gun has been found.

Me: Motor Shaft turns now that I’ve removed the broken Impeller

AI: That’s a huge clue, Byron—and it narrows the failure down beautifully.

🧠 Diagnosis update: Impeller jam, not motor seizure

The fact that the motor shaft now turns freely confirms the motor itself is not seized.

The impeller was likely jammed by debris, warped from heat, or cracked and wedged against the diffuser or volute.

That jam caused the motor to hum under load, overheat, and trip its thermal protection.

🔍 What to inspect next

Impeller condition: Look for cracks, melted edges, or embedded debris.

Diffuser and seal plate: Check for scoring, warping, or signs of cavitation.

Shaft seal: If water breached into the motor side, you may see rust or white residue around the seal cavity.

Motor windings: If you want to be thorough, pop the motor end cap and inspect for heat damage or bearing wear.

🛠️ Repair path forward

If the motor spins freely and tests electrically sound (no open or shorted windings), you may be able to:

Replace the impeller and seal kit

Clean the volute and diffuser

Reassemble with proper alignment and vibration isolation

This could save you from a full pump replacement—especially if the motor’s still strong. Want help sourcing a compatible impeller and seal kit or prepping a reassembly checklist to avoid future jams?

I wasn’t familiar with the terms of that AI was using to describe the pump components. This is where I found the pump diagram to help me translate the technical words. AI is smart and it’s the only tool that I’m aware of that you can ask how best to use it. In my case I didn’t want AI to go layman on me, instead I needed to up my game and use the technical words for the next phase of the project.

I decided to repair rather than replace. I found a repair kit for my pump model on Home Depot’s website for about $70. The kit included everything inside the pump between the Volute and the Seal Plate. Here is a link to the kit I used.

Assembly

After receiving the repair kit I immediately began putting the pump back together. I did run into some problems. Some of these issues turned out to be minor but there was one that was a real hard problem to figure out. The first problem I ran into was a broken rubber washer that was located between the Motor and the Sealplate. It was a rubber washer and it broken when I removed the motor to access the back of the Shaft Seal. The Shaft Seal is a ceramic disk encased in rubber that sits inside the hole where the motor shaft enters the Sealplate. It doesn’t show up on the diagram so I was a little surprised to find it. Turns out that rubber washer is used to dampen vibration. I tried to get a new one from the local hardware store but they didn’t have an exact match. I bought one that was close and used that in my install. Later I ended up taking that out and replacing it with the original but that decision came with the hardest problem I solved.

The second problem I ran into was simply trying to reconnect the Volute to the Sealplate. Originally to remove the Volute I need a small pry bar to separate the Volute from the Sealplate. The Volute is torqued onto the Sealplate so it took some effort to get them separated. I had much difficulty getting the Volute back on. I ended up using dishsoap to lubricate the head on the Diffuser so that it was easier to insert into the mount point on the inside of the Volute. Mind you AI didn’t mention anything about dish soap. Instead I found a video from Wayne pumps illustrating how to perform a pump repair. I think this was the only time I went to the internet myself to find information. I may have even found that video after purchasing the repair kit.

Most every project has a gottcha moment. The third problem I ran into was that moment. You see after I assembled the pump and began torquing the Volute down on the Sealplate I was testing my work by spinning the motor shaft manually. After a few rotations the shaft would begin to seize. It didn’t matter which direction I spun the motor shaft.

Me: yes, it doesn’t spin freely. it moves then gets harder to move until it stops. This happens no matter what direction I turn it

AI: That’s a clear sign of impeller binding or shaft misalignment, Byron—and it’s good you caught it now. Here’s how to troubleshoot it methodically:

🔍 Top causes of shaft resistance after volute torque

Impeller rubbing against volute or diffuser

Over-torquing can compress the seal plate and shift the impeller forward.

Check for contact marks or scraping on the impeller blades or volute cavity.

Shaft seal not seated fully

If the ceramic or carbon face isn’t flush, it can tilt the impeller or bind the shaft.

Recheck seal depth and orientation.

Motor misalignment due to base washer or uneven torque

If the motor isn’t sitting flat (especially with a cracked or missing rubber washer), the shaft may tilt and bind.

Confirm even torque across all motor mount bolts.

Debris or corrosion inside the volute or seal plate

Even a small flake of rust or leftover gasket material can cause interference.

Clean all mating surfaces thoroughly.

🧰 Byron-style fix checklist

Loosen volute bolts slightly and test shaft rotation again.

Remove volute and inspect impeller clearance and seal plate alignment.

Confirm shaft seal is fully seated and not cocked.

Reinstall with even torque in a star pattern—start at 50%, test spin, then torque to spec.

Want help logging each torque stage and clearance check into a reusable reassembly workflow? We can build it step-by-step so future rebuilds are even smoother.

What I didn’t realize is that AI had just provided me the answer to my problem. Instead I assumed that the rubber washer I replaced was the culprit because it was slightly bigger than the original so I thought that maybe it pushed the impeller assembly to far forward causing the binding. I then decided to disassemble the pump and replace the new rubber washer with the cracked old one. Keep in mind that once I understood it was for vibration damping, it didn’t matter that it was cracked. This happened to be the first of many assemble – disassemble routines I went through. Each time trying to figure out why the impeller was binding up. I ended up going back and forth with AI about what might be happening. Rather than include all that material here let’s just say that AI and I had a robust conversation trying to troubleshoot the problem. I’d say it felt very much like I was talking to an expert on my team. I was near giving up but if you know me, I don’t give up easy. Instead I let the problem stew overnight and tried again the next day. That cycle repeated another couple of days until my perseverance prevailed.

Finally after performing a rebuild for about the 7th time, I figured out what was going on. I want to remind you that AI actually told me what was wrong at the very beginning of my work. AI said “That’s a clear sign of impeller binding or shaft misalignment“. I didn’t actually understand what was meant by shaft misalignment and I didn’t bother to ask what AI meant. I simply figured how can the shaft be misaligned when it bolts into the housing. It wasn’t like I changed anything related to the shaft. However, what actually was the problem was a misalignment on a component through which the shaft penetrates. The problem was a very subtle misalignment of one of the components of the Shaft Seal Assembly. During one of the assembly cycles, the Shaft Seal Assembly came apart. I didn’t realize there was a specific way the assembly goes together and of course my luck meant that it was 1/4 turn off of its correct orientation. Take a peek at the pictures below to see what I mean.

The first image shows the parts individually and you can clearly see there are alignment guides on the metal portion of the assembly and the rubber mount on the spring have a groove mold where metal sleeve is to insert. The second image shows the two pieces together with proper alignment. What you don’t realize is that because this is a spring loaded mechanism it is super easy to install with a misalignment which only become a problem when the spring is compressed. Before spring compression you can’t necessarily tell the pieces are out of alignment. As the impeller is screwed into position it will eventually compress the spring. When the components are out of alignment the metal alignment guide begins compressing the rubber until the rubber cannot be compressed anymore thus causing the impeller to seat higher. This higher seating position causes the Impeller to drag on the Diffuser ultimately causing the Impeller to unseat and seize the motor shaft. This was the root cause of my problem.

Conclusion

It pays to be persistent and patient. I was able to get my pump back into service for $70. What I learned was very valuable. While I could have done this project without AI, I don’t think I would have been as educated afterwards. For example, knowing the right words to use makes conversations faster and more accurate. Believe it or not AI was also encouraging, like a coach. I was amazed at the knowledge available with AI, for free. I learned so much because it’s my nature to ask a lot of questions. Each line of questions brought me into a rabbit hole of information. I learned how interact with AI much better and when to recognize that AI is off the path or even hallucinating. I had to correct AI a couple of times just like I would have done with an expert team member based on my understanding of the problem space. It was an exhilarating experience, yes it had some frustrating aspects to it but what good project doesn’t. Until AI becomes more capable, nobody should be worried that AI will take your job but you better educate yourself on how to work with AI or you will be left behind.